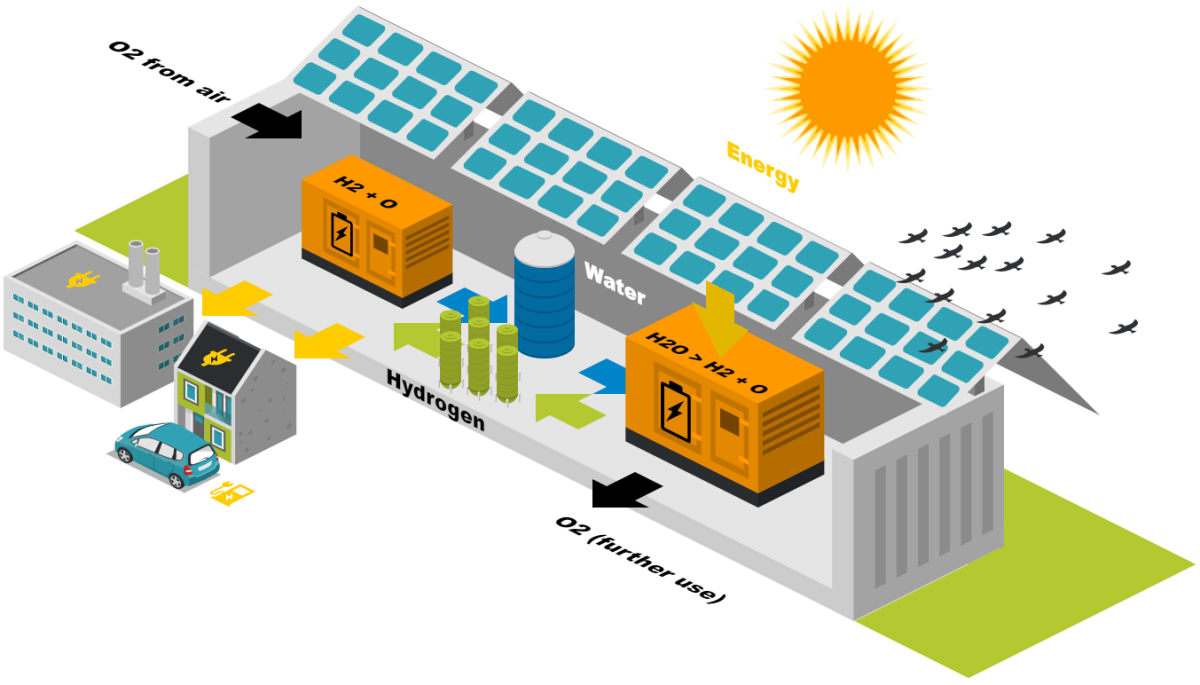

The Micro-Grid is the basis for the construction of the Hydrogen Tryout Area in South Africa. All the necessary components of the micro-grid are contained in a transportable housing, for example a shipping container. The solar cells on the roof of the container convert the solar energy from sunlight into electricity. This electricity is used to produce hydrogen and oxygen from fresh water in the electrolyser.

The hydrogen is compressed and stored in suitable gas cylinders. If electricity is needed, the hydrogen can be converted back into electricity by feeding in ambient air (oxygen) via a fuel cell stack. The waste product is water. This is stored in a tank and made available for electrolysis as needed. This creates a closed water circuit that only needs to be filled at the beginning and then works almost loss-free. Therefore, no fresh water needs to be added during operation.

DIVERSE APPLICATIONS FOR SUSTAINABLE POWER SUPPLY

The electricity generated by the fuel cell can be used in a variety of applications:

- the self-sufficient supply of electricity to private households

- ensuring an uninterruptible power supply for industrial companies or

- charging batteries in electromobility.

The oxygen produced during electrolysis can also be used for other applications:

- as an additive for biological water treatment or

- for the supply of oxygen to care facilities

The microgrid is designed in such a way that the installed photovoltaics are sufficient to operate the electrolyser. If it is possible to equip other areas in the vicinity with photovoltaics or to support the system with electricity from wind power, the electricity generated can be used directly during the day and only the surpluses are used to produce hydrogen, which in turn ensures the power supply at night.

CONSTRUCTION OF THE HYTRA MICRO-GRID

The micro-grid is designed in a modular way, so the different components can be exchanged if necessary. If more electricity is available, for example, a larger electrolyser can be installed. If there are more hours of sunshine, more hydrogen can be produced, which makes a larger hydrogen storage unit necessary.

The design depends not only on the installation conditions and the application, but also on the investment. Therefore, the correct design and selection of components is necessary.

ADVANTAGES

The essential feature of the HyTrA micro-grid is that it will be perfectly adapted to the climatic conditions and resulting requirements of the African market. Specifically, this means that it will have a robust, safe technological solution with a lifetime of 60,000 operating hours (more than 10 years).

It will also address issues of storage density, safety, ease of use, freedom from maintenance and energy self-sufficiency. In addition, the production of the micro-grid will be optimised with the participating companies so that efficient procedures and processes can be realised that make it possible to use economies of scale to ultimately generate cost parity with regard to fossil alternatives.

By using hydrogen as a storage medium, it is thus possible to supply self-sufficient off-grid systems with energy seasonally and independent of the time of day. Thus, an important step for the energy transition and for saving emissions can be realised.